February 23, 2023

Smart maintenance can significantly reduce the environmental footprint and cost of production

The competitiveness and survival of industrial companies today are closely linked to the sustainability of their production and products. We see initiatives like fossil-free steel, electrification, emission compensation services, etc., but are there ways how all manufacturing companies can reduce their environmental impact with small means in their existing production?

Quant, a front-runner in maintenance development, has, over the last 30 years, developed their platform for Smart Maintenance, where Sustainability is a cornerstone. We believe that well-structured maintenance can impact and support any manufacturing company’s aspirations to become a leader in the field of sustainable production.

Four main dimensions

There are four main dimensions impacting sustainability in Maintenance Operations. The Human dimension plays a central role in all sustainability centred ambitions related to asset management, when taking over a maintenance department, Quant put´s all focus to ensure the right conditions for safety, diversity, and inclusion as well as training and skills improvement, among other things.

The Technical and Life Cycle dimensions are two other key contributors to sustainable production. Where Maintenance Effectiveness, Reliability Centred Maintenance combined with Plant Performance Improvement will help impact Overall Equipment Effectiveness as well as indirect and direct life Cycle Cost.

-Our role as a maintenance partner means bringing the know-how and structure to take the maintenance to the next level. Excellent results can be achieved when working with proven processes and integrated digital tools, says Joakim Christoffersson, Business Developer, Quant Sweden.

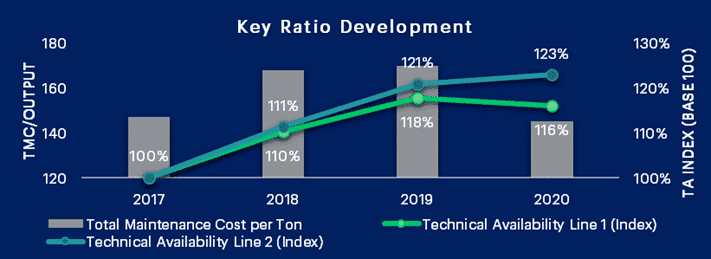

-Continuous plant performance improvement is integral to a maintenance partnership with Quant. For example, we helped a European cable producer significantly increase the technical availability at one of their plants. This enabled the customer to increase their output without investing in additional production capacity – and all environmental aspects related to that, says Christoffersson.

The Environmental dimensions in Industrial and manufacturing companies’ products have a significant impact on energy and resource usage, as well as on potentially harmful emissions and compliance with standards and regulations. Sustainable manufacturing will increase the need for structured and well-managed maintenance to achieve sustainability gains from in a structured and compliant way.

– It can be from performing as an energy optimization study of a process line, buy equipment based on their life cycle support cost rather initial acquisition cost, to using the right lubricant for an equipment generating less wear and tear.

Effective support right from the day one

Quant engages and supports clients in various situations through the life cycle of production, such as in building and greenfield projects, transformation and maintaining with effective support right from the day one, where the goal is to make a measurable and sustainable difference for our customers.

-The focus of all our engagements is to set up an effective organisation, culture, processes, tools, and systems, all in all, aimed to optimise output and return on capital employed for our clients in a sustainable way, Christoffersson says.